Standard Function

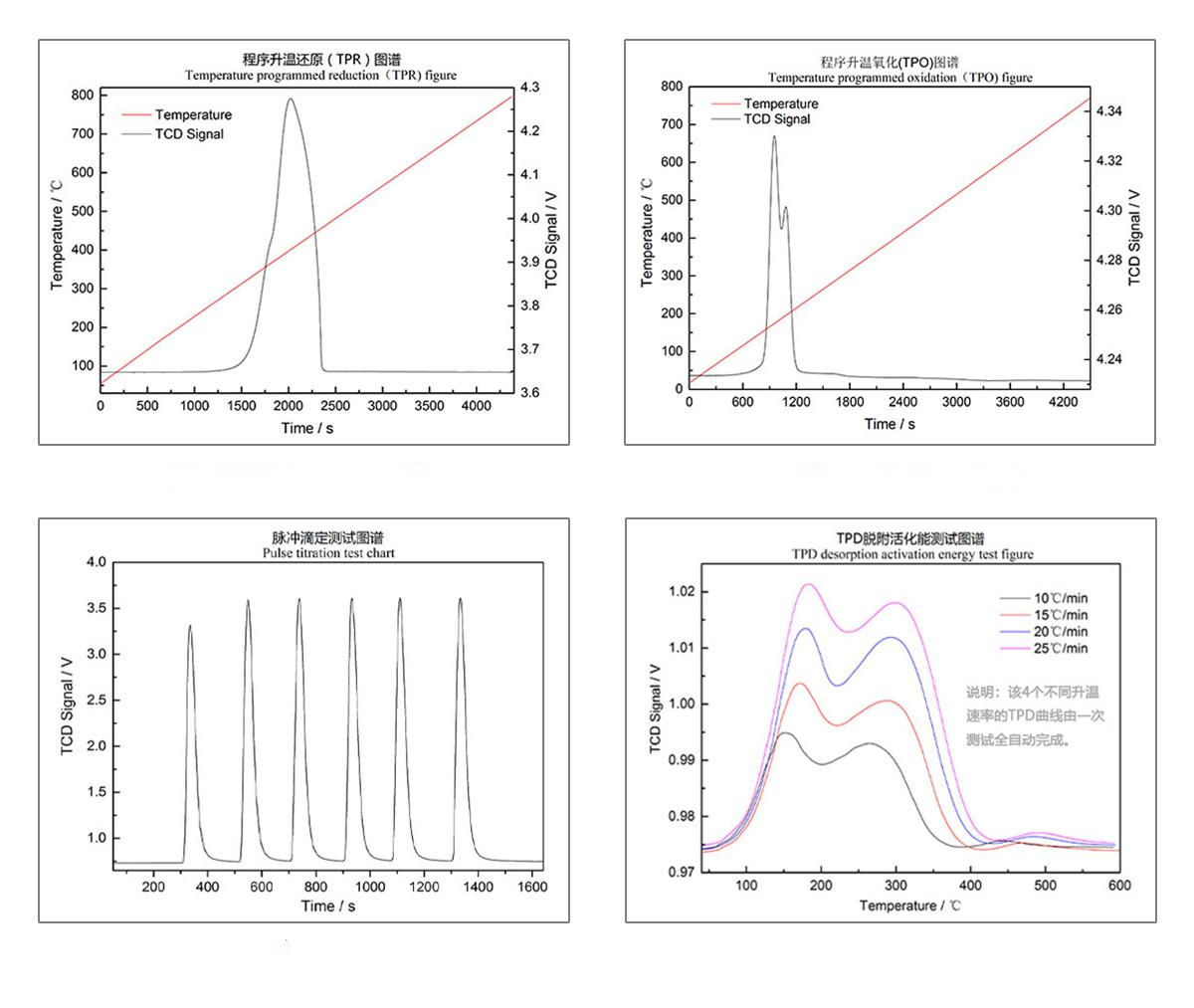

- Temperature Programmed Desorption (TPD)

- Temperature Programmed Reduction (TPR)

- Temperature Programmed Oxidization (TPO)

- Temperature Programmed surface reaction (TPSR)

- Temperature Programmed Sulfidization (TPS)

- Pulse Titration

- Desorption Kinetics:

- Desorption activation energy (Ed)

- Preexponential factor A of desorption (Ad)

- Desorption order (n)

- Multi-temperature points

- Automatic ProgrammedReaction:

- Automatic cycle lifetime assessment;

- Programmable multi-step reactionprocess;

- Automatic multi-temperature points execution.

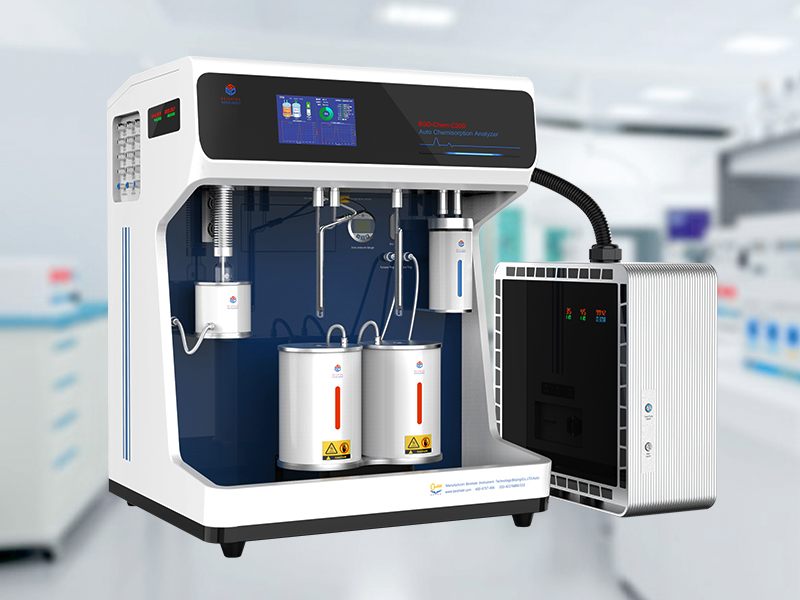

Technical Parameter

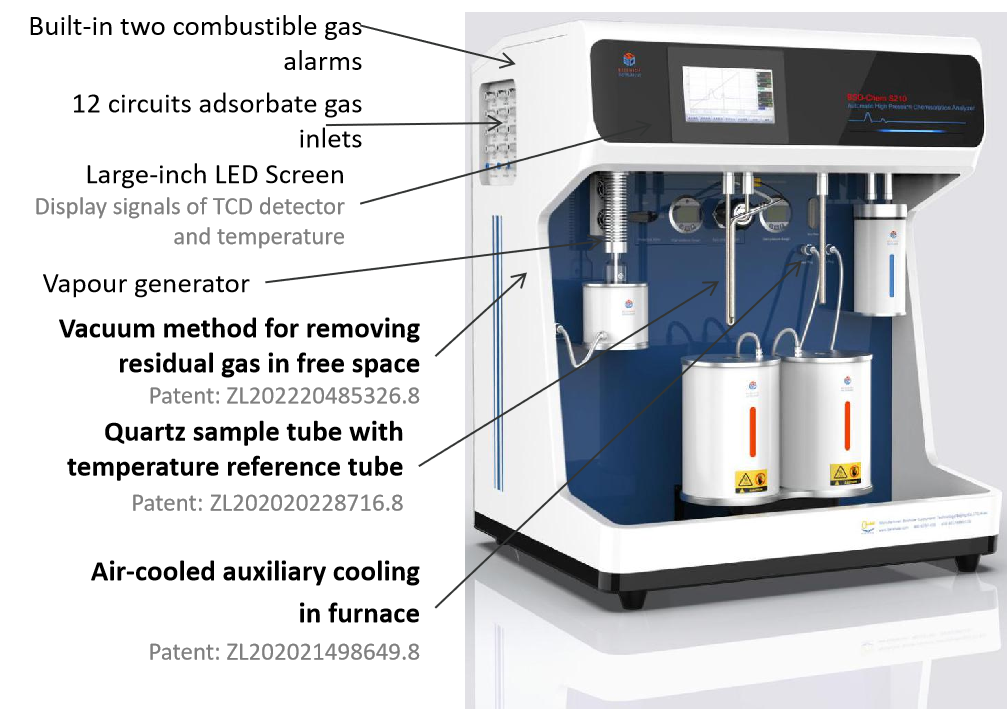

- Temperature programmed: program-controlled heating and cooling, rate: 1 centigrade/min to 100 centigrade/min;

- 2 high-temperature furnaces,range from room temperature to 1473K, two furnaces switch automatically and work for heating and cooling in turns;

- Support 12 gas pipeline analysis;

- Mass Flow Controller (MFC): Support 3gas pipelines, support gas mixture chemistry adsorption;

- Adsorbate type: Non-corrosive and corrosive gas, vapour, etc.,

- Test pressure: Standard Normal pressure; 1Mpa, 3Mpa, 10Mpa(Optional);

- Pulse Titration: Standard measurable tube 0.5ml, optional1ml and 5ml;

- Vacuum pump: eliminate the effect of residual gas in free space of pipeline;

- Cold trap: eliminate effect of low-boiling point components vapor (e.g. water) on concentration detection;

- Vapor Generator, generate vapor for chemisorption;

- Sample tube: Quartz U-shaped sample tube with temperature reference tube;

- Thermostat system: Double systems for thermostat, gas circuit system support from 313Kto 353K while TCD system supports from 333K to 383K;

- External marked sampler: Standard 1ml sampler; other volumes (Optional);

- Two combustible gas alarms: Monitor different areas in real-time, avoiding leakage of combustible gas;

- Two detection modes of TCD detector: Support switching high sensitivity mode and wide range mode, meet test’s requirement of weak signal and strong signal;

- Detection system: default TCD detection system, Optional MS detection and infrared system.

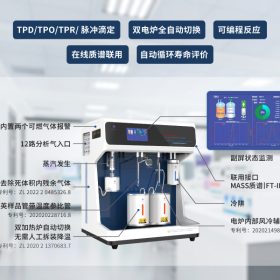

Characteristic Structure

Technical Advantages

- Full automatic test:dual heating furnace automatic switching, no need to wait for pre-treatment cooling, directly switch to the other furnace for testing, without human intervention;

- Vacuum clean residual gas: built-in vacuum pump to remove residual gas in free space, reduce baseline drift and improve test accuracy;

- Temperature reference tube: temperature sensor is placed in reference tube of the sample tube (the sensor and sample are in the same environment), ensure high accuracy of temperature control and measurement.

- Automatic air-cooled cooling system:equipped with an air-cooled tube and a temperature detector at the air-cooled site, automatically detect the temperature of the heating furnace and turn on the air-cooled cooling system to prepare for the next test;

- Multi-step continuous automatic test: fully automatic execute edited multi-step test program, used to evaluate the catalytic performance and chemical adsorption performance of materials under complex reaction conditions;

- Automatic cycle test: pre-treatment and test automatically cycle, used to evaluate the lifetime and chemisorption stability of materials;

- Support ultra-low temperature thermostat & ultra-low temperature programmed temperature rising, realize ultra-low temp test;

- High standard configuration: standard vapor generator, pulsed titration system;

- Support test of mixing 3 analysis gas, standard 3 gas MFC and support 3-gas mixture test;

- High reliability and durability;

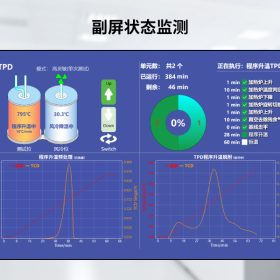

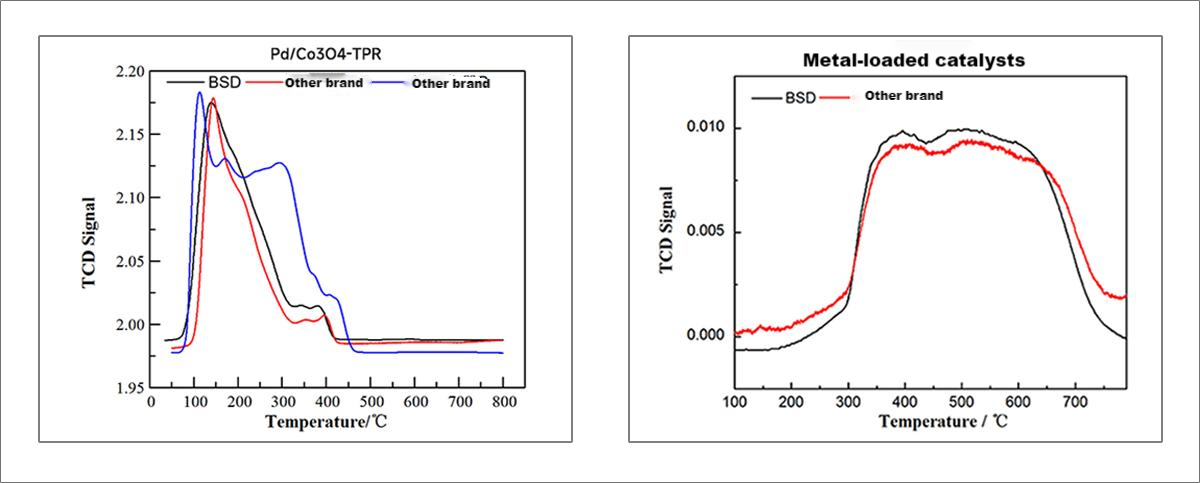

Comparison test result

Application data report

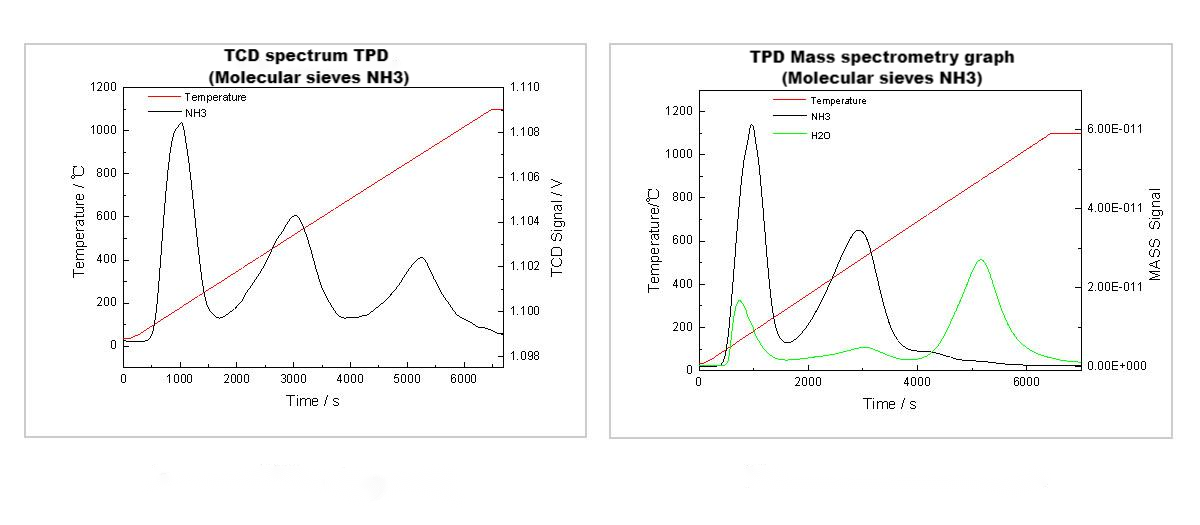

For right graph: Three NH₃ desorption peaks appeared at 463K, 723K,1173K; if the desorption peak at 1173K is NH₃’s, it is not in line with the characteristic of the material and expectations of the researchers.

For left graph: Two NH₃ desorption peaks appeared at 463K and 723K while small amount of H₂O desorption, the desorption peaks at 1173K is the H₂O’s, in line with characteristic (Not desorb NH₃ )of the material.

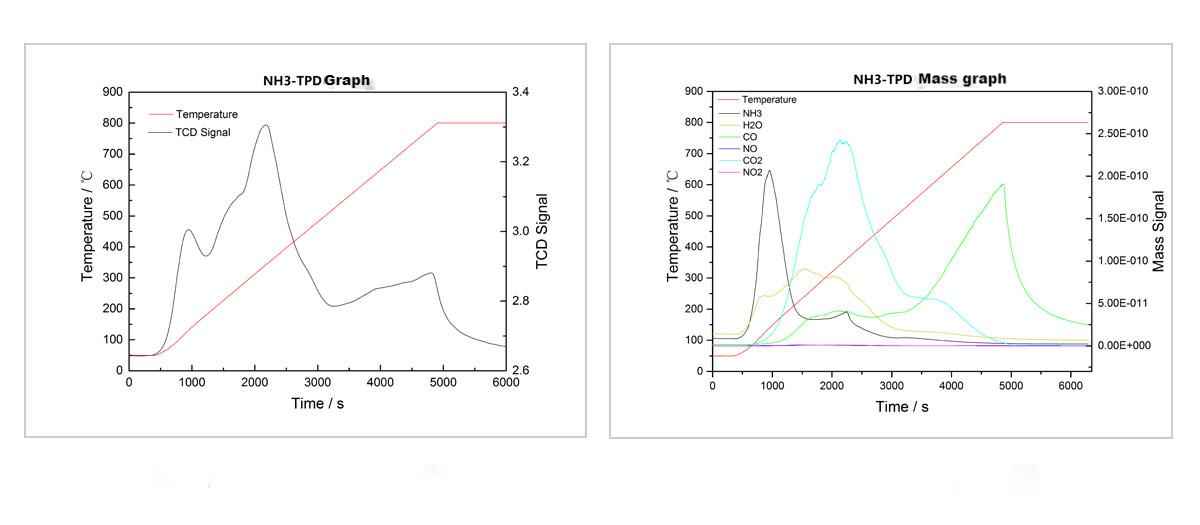

For right graph: Three NH₃ desorption peaks appeared at 398K,623K and 973K;

For left graph: NH₃ desorption peak appeared at 398K; small NH₃ desorption peak appeared at 623K; H₂O desorption peak appeared at 513K; CO₂ desorption peak appeared at 623K; CO desorption peak appeared at573K and 973K;

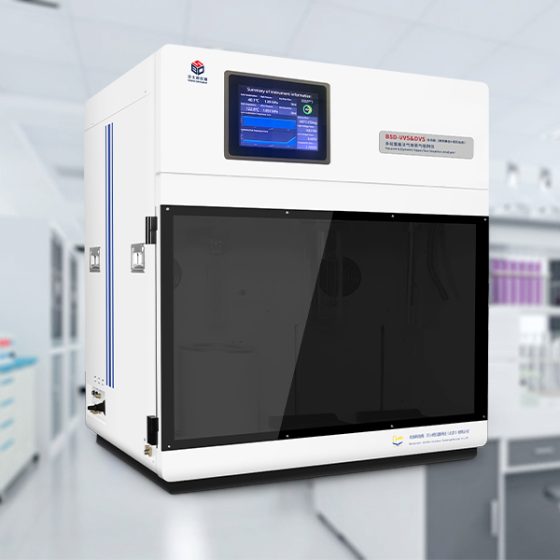

Coupled with on-line mass spectrometer and Infrared

- Mass spectrometry interface;

- Real time monitor in TPSR;

- Obtain concentration curve.

- FT-IRinterface, optional model Nicolet iS20,Nicolet Summit (ThermoFisher)

- Optional gas accessories,

- Optional solid accessories;