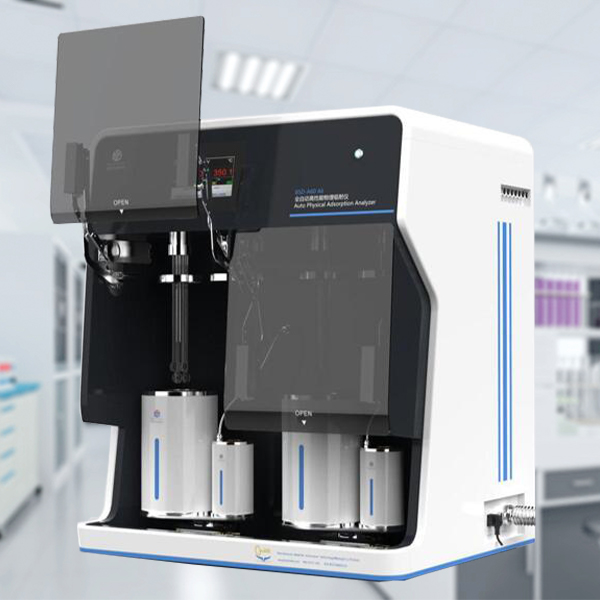

Main Function

Specific surface area and meso-, micro-, and ultramicroporous analysis;

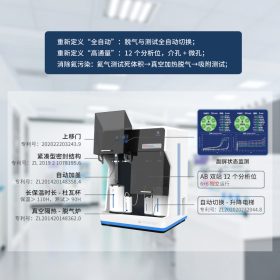

High-throughput: Support 2/3/6/9/12 sample test;

Fully automatic: Switch degas and test automatically without human operation;

High configuration: Double molecular pumps for A/B analysis stations, use molecular to vacuum degas;

Anti-pollution: Degas micro-pore materialsthrough pressure controlled heating to reduce pollution;

No Helium contamination: Helium test temperature area first, automatic degassing followed;

Auto cycle: Adsorbent cycle sorption performance automatic assessment;

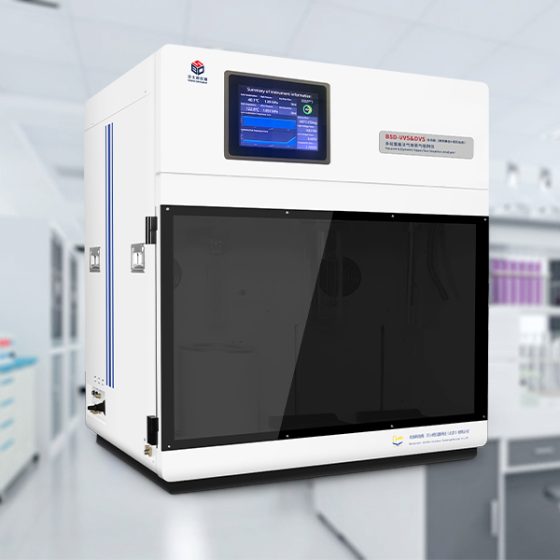

Regular gas sorption:N₂, O₂, CO, CO₂, Ar and etc,Vapor Adsorption, such as H2O, Ethanol,Organic Vapors;Other gas, such as Hydrocarbon C1-C4, CO, NH3;

Combustible gas sorption:H₂, CH₄, C₂H₆, etc alkanes and alkynes;

Technical Parameter

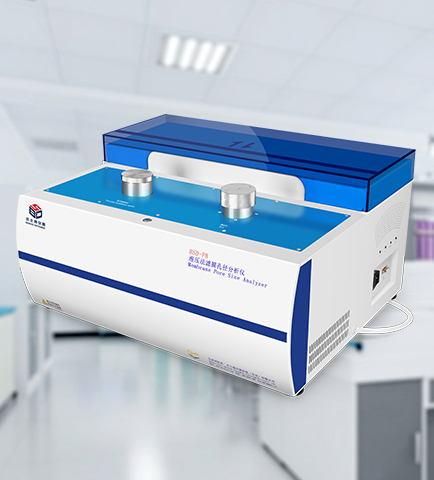

Large test range: SSA≥0005㎡/g, pore size: from 0.35nm to 500nm;

Test efficiency: Multi-point BET (exclude degas), 12 samples/hour in standard mode, 12 samples/ 15 minutes in fast testing mode;

High accuracy: Quantitative error of SSA, pore size, pore volume, adsorption capacity less than 0.5% RSD (based on the standard sample BET value);

Program control heating for degas: Software control heating, temperature range from room temp to 400 centigrade, accuracy better than 0.1 centigrade;

Software intelligent degassing finishment judgement: Software automatically judge degassing with pressures change;

Anti-flutter degas: Pressure and temperature change determined by program, based on the value control furnace lift (up for heating or down for cooling);

Vacuum can reach 10-2 Pa with oil sealed pump while can reach 10-8Pa with molecular pump.

System equipped with 3 pressure transducers: 0-1000mmHg – 0,12% of reading, 0-10 mmHg – 0,12% of reading and 0-0,1 mmHg – 0,15% of reading and resolution 10-7 mmHg

Minimum measurable pore volume≥ 0.0001 cc/g and total Surface area from 0,1m2 for nitrogen unit and 0,01m2 for Krypton

Internal gas pipeline system keep thermostatic at 40°C; accuracy beter than 0,1°C

Thermal Dewar’s Cup -3L

Manifold made of Stainless Steal

Programmable number of measurement points from 1 to 5000

Saturation pressure can be measured, entered by the user or calculated

Device equipped with a heater that allows measurements to be taken at temperatures higher than room temperature

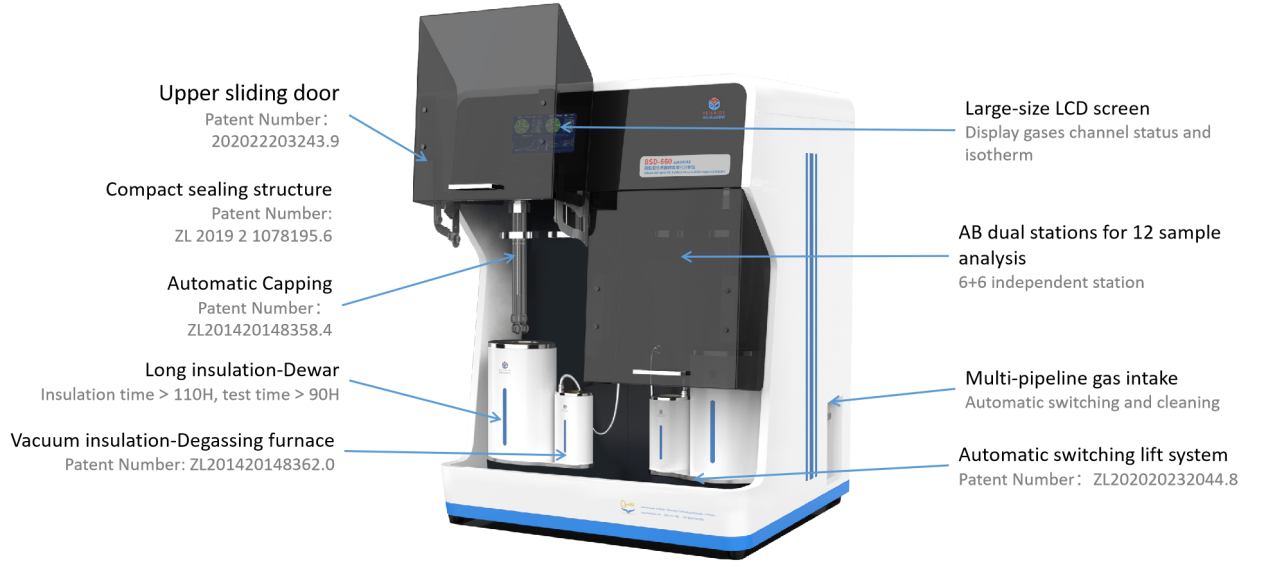

Characteristic Structure

Technical Advantages

- High-throughput: up to 12 samples analyzed in one time;

- Fully automatic: Switch degas and test automatically without human operation;

- High utilization of time :Realize loading samples after work and checking the data in the next day;

- Completely eliminate He pollution: Helium test temperature area first, automatic degassing followed, solve He pollution of microporous material analysis in worldwide;

- Anti-flutter degas: Pressure and temperature change determined by program, based on the value control furnace lift (up for heating or down for cooling);

- Auto cycle: Adsorbent cycle sorption performance automatic assessment by degassing and testing automatically test;

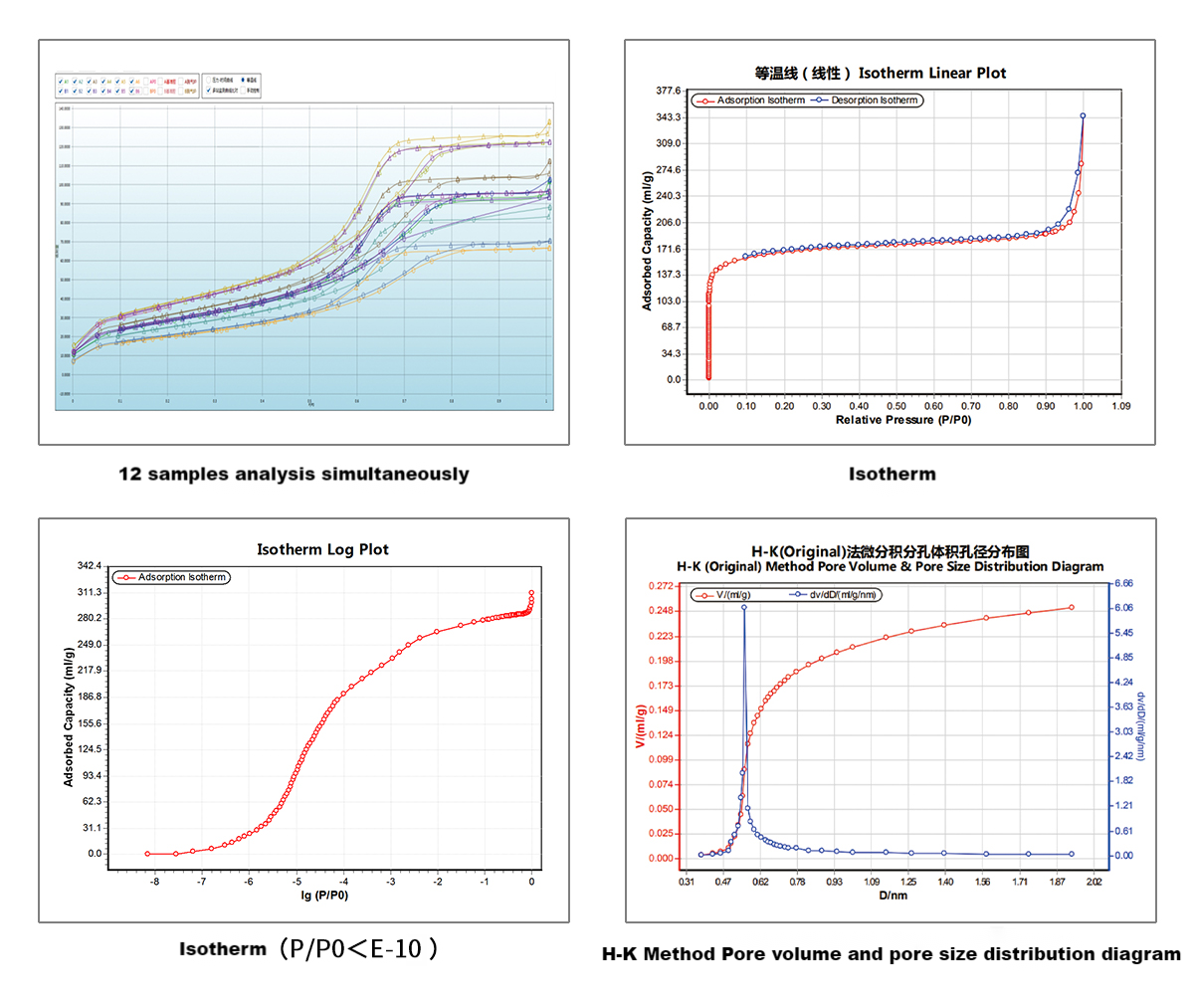

Data Report

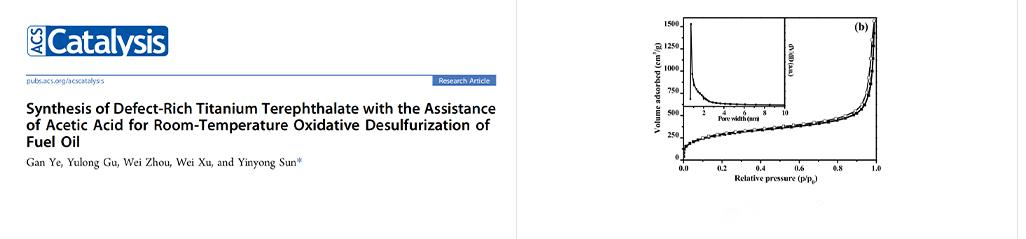

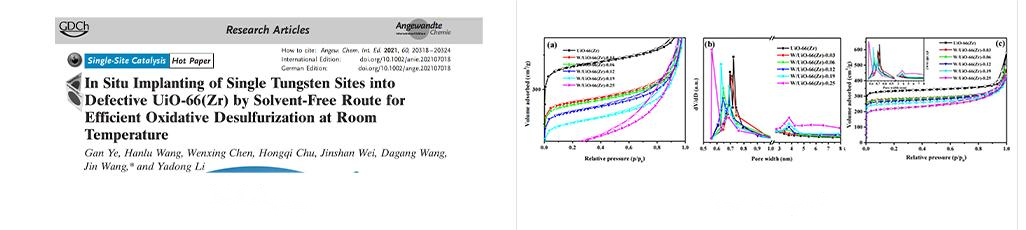

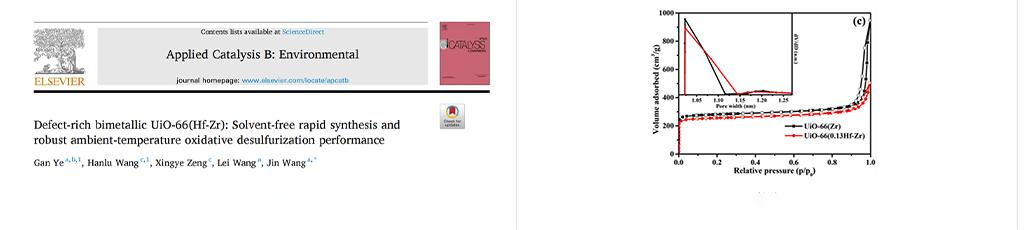

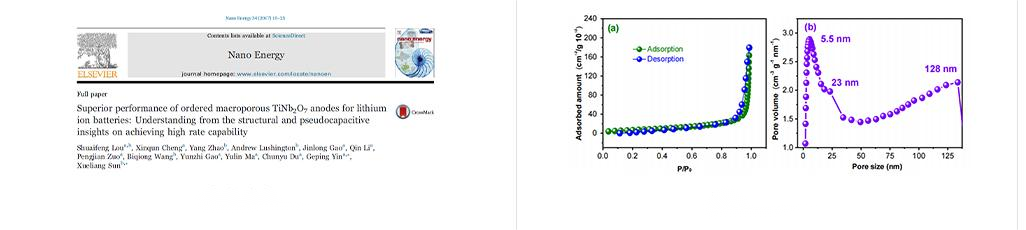

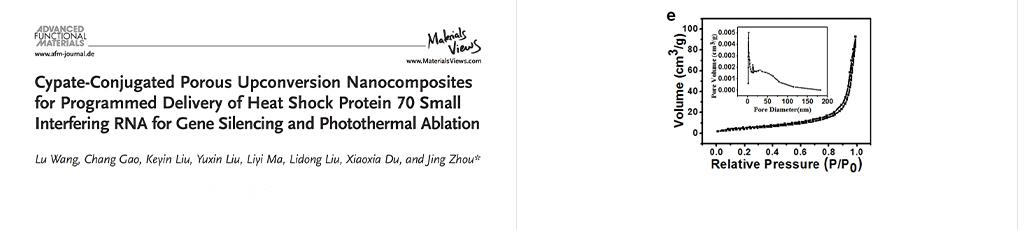

BSD-660 Application Paper

BET analysis,measure surface area,pore size distribution,Pore Volume,BET surface analysis,area and surface area,surface measure,surface area analyser,Surface Area,BET surface analyzer,surface area testing,BET Surface Area,Surface Area Analyzer,BET porosity measurement,Surface Area and Micropore Analyzer,BET surface,BET measurement,BET surface area analyzer price,BET surface area analyser,BET analysis instrument,surface area analyzer instrument

BET Surface Area Analyzer,BET analysis,BET surface area analysis instrument price,BET surface analyser,BET surface area analyser price,BET surface area measurement,surface area and pore size analyzer,surface area analyzer principle

Surface Area and Pore Size,Surface Analyzer,Pore Size Distribution,BET instrument,Surface Area Analyzer Principle,Surface Area And Micropores,BET Specific Surface Area,BET Surface Area Testing,Surface Area And Pore Size,BET adsorption,BET adsorption analyzer,BET theory Surface area,BET theory Specific surface area,BET theory test,BET theory analyzer,Mesopore analysis,Mesopore analyzer,Mesopore volume,Mesopore size,Mesopore detection,Mesopore measurement,Mesopore test,Mesopore tester,Mesopore structure,Low temperature Nitrogen adsorption,Low temperature Nitrogen adsorption analyzer,Pore volume analyzer,Pore volume measurement instrument,Pore volume detector

Pore volume tester,Pore volume analysis,Pore volume and pore size,Pore volume and pore size analyzer,Pore volume and pore size detect,Pore volume and pore size detector,Pore volume and pore size measurement,Pore volume and pore size measuring instrument,Pore volume and pore size test,Pore volume and pore size tester,Pore volume analysis,Pore size/diameter analysis,Pore size distribution analyzer,Pore size analysis,Pore size analyzer,Pore size detection

Pore detector,Pore measuring ,Pore measuring instrument,Pore size test,Pore size tester,Pore structure,Pore structure distribution,Pore structure,Pore structure analyzer,Pore structure detection,Pore structure detector,Pore structure measure,Pore structure measuring instrument,Pore structure test,Pore structure tester,Porosity analysis,Porosity analyzer,Porosity detection,Porosity detector,Porosity measurement,Porosity measuring instrument,Porosity test,Porosity tester,Porosity,Porosity analysis,Porosity analyzer,Porosity detection,Porosity detector,Porosity measurement,Porosity measuring instrument,Porosity test,Porosity tester,Micropore analysis,Micropore analyzer,Micropore volume analyzer,Micropore size analyzer,Micropore porosity,Micropore porosity,Micropore detection,Micropore detector,Micropore measurement,Micropore measuring instrument,Micropore test,Micropore tester,Nonwoven fabric pore size analyzer,Specific surface,Specific surface metrology,Specific surface analysis,Specific surface analyzer,Surface specific area and pore size analyzer,Specific surfacedetection,Specific surface detector,Specific surface measurement

Specific surface measuring instrument,Specific surface test,Specific surface tester,Specific surface area,specific surface area analyzer,Specific surface area analysis,Specific surface area analyzer,Specific surface area and pore size analyzer

Specific surface and pore size analyzer,Specific surface area and porosity analyzer,Specific surface area and porosity analyzer,Specific surface area detection,Specific surface area detector,Specific surface area measurement,Specific surface area measurement instrument,Specific surface area test,Specific surface area tester