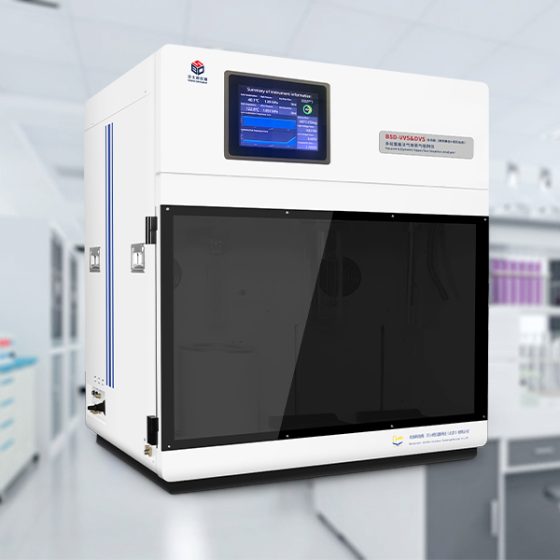

Analizador automático de densidad real de la serie BSD-TD

(Método de reemplazo de expansión de gas)

- True density test for powders, granules, lumps, flakes, liquid, slurry and etc;

- Porosity analysis for block material, foamed material, cores, metallic elements and etc.

Test Function

- True density test for powders, granules, lumps, flakes, liquid, slurry and etc;

- Porosity analysis for block material, foamed material, cores, metallic elements and etc.

Principio de prueba

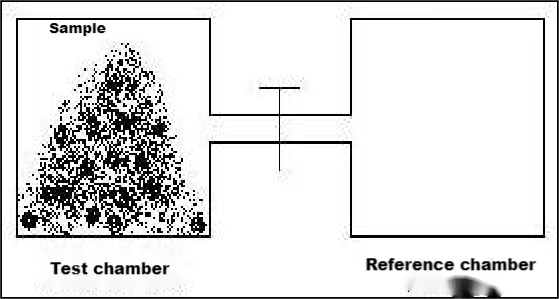

- Archimedes’ principle – gas expansion replacement method, use Bohr’s law (PV=nRT)of small diameter inert gas (He) under a certain condition, accurately obtain the skeleton volume of the sample (including closed pores) by determining the volume of gas replaced by the sample in the test cavity to acquire the true density which equals mass/ skeleton volume.

- Gas expansion replacement methodis to use gas rather liquid to determine the gas volume replaced by the sample, avoiding test errors caused by sample dissolution in liquid immersion method and protect the sample from damaging. The gas penetrates into very small pores of sample and the irregular pores on the surface, the measured sample volume is closer to the skeleton volume of the sample, which can be used to calculate the density of the sample, and the test value is closer to the true density of the sample.

- The instrument test system consists of a test cavity and a reference cavity.

Modelo específico

- BSD-TD Automatic True Density Analyze

- BSD-TD-K Automatic True Density & Porosity Analyzer

Technical parameter

- Test content: True density, opening and closing porosity

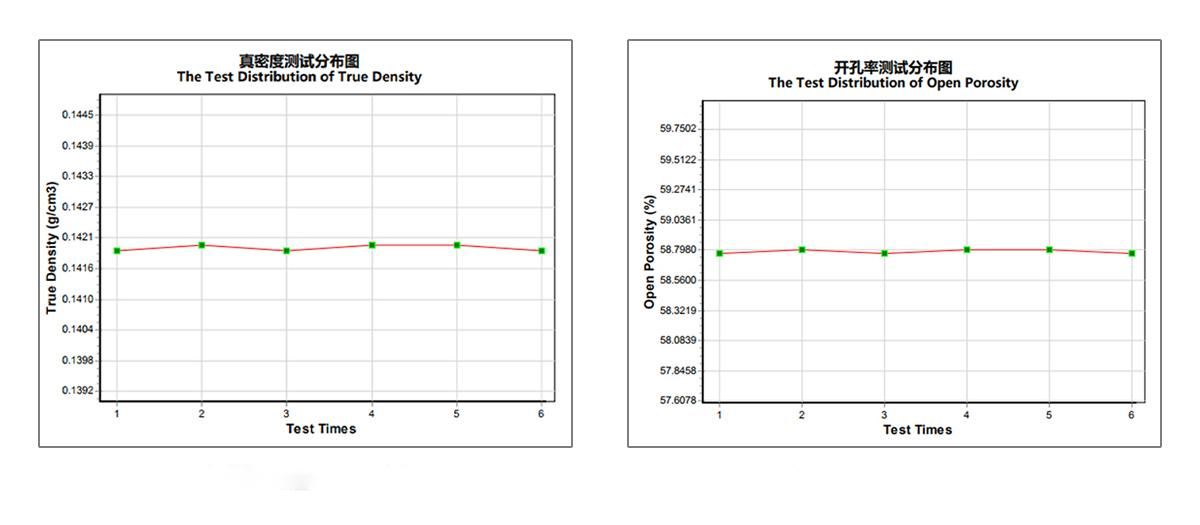

- Test accuracy: Accuracy better than ±0.03%, repeatability better than ±0.015%, resolution: 0.0001g/ml;

- Test speed: The whole test process is completed in 0.5 to 1min at a single analysis station, and the analysis efficiency of the two stations is improved;

- Number of analysis stations:Opcional 1/2 stations

- Sample type: Not limiteddensity of sample. Various solid samples in powder, particle, block, foam, as well as slurry, nonvolatile liquid and other samples.

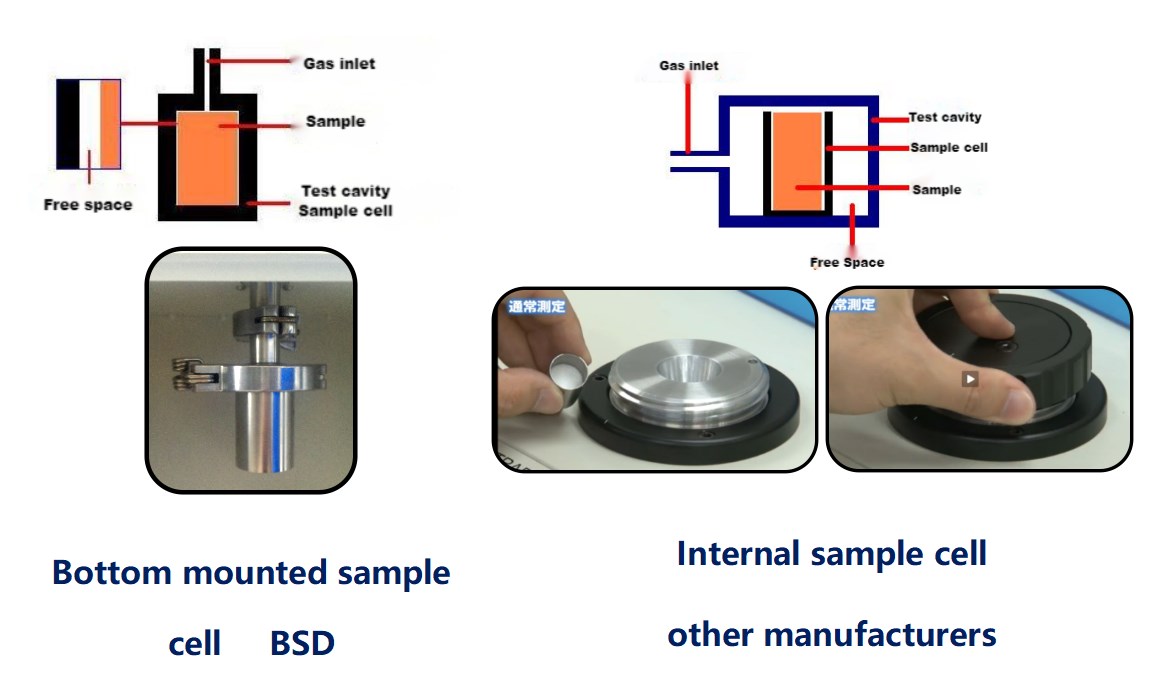

- Test mode:The sample pool is directly used as the sample test cavity, which has the advantage of high utilization of the sample test cavityvolume compared with similar instruments, so that the test accuracy can be improved;

- Isothermalmode: automatic programmed constant temperature mode, constant temperature accuracy error <0.1 centígrado; Programmed control of constant temperature process, and automatically enter the test process;

- Pneumatic control valve: Pneumatic control valve, fundamentally and completely eliminated the similar instruments solenoid valve structure action caused by the heat of the reference chamber volume changes;

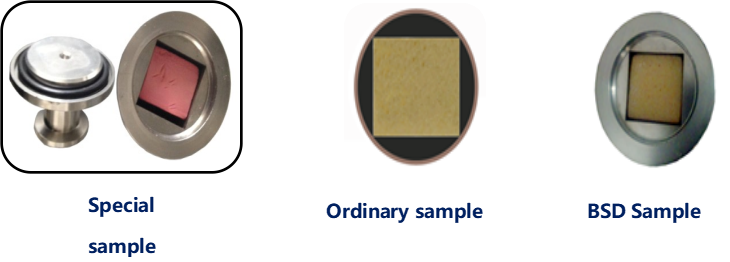

- Internal square sample cell: Dedicated for testing the opening and closing porosity, which can reduce errors for block samples;

- Reference cavity: Equipped with 1 built-in reference cavity and 1 extended cavity; The expansion cavitycan improve testing accuracy for different sample cell volumes; The program automatically selects whether to enable the expansion cavity based on the sample cell volume.

Technical advantages

- According to the requirements of national standard GBT 10799-2008 for the determination of open and closed cell volume percentage of rigid foam, a special sample pool for open and closed cell percentage was designed.

- Ordinary sample pool:The cylindrical sample cell is suitable for cylindrical samples. When using a cube sample, there will be a lot of space, and the volume utilization rate of the sample cell is less than 50%, which has a significant impact on the testing of open and closed porosity;

- BSD Sample Cell:The rectangular sample cell is suitable for rectangular samples, and the volume utilization rate of the sample cell exceeds 80%, which is more conducive to testing the opening and closing porosity. Stainless steel metal sample pool is durable.

- Two regular cylinders with a cross section size of 6.25cm2 and a height of 2.5cm (Optional size); Two regular cubes of 2.5cm*2.5cm*2.5cm (Standard size)

- Regular cubes are relatively easy to cut, ordinary tools can be used, and the appearance volume is simple to measure;

- Regular cylinders are extremely difficult to cut unless the relevant professional cutting tools are used, and it is inconvenient to measure the apparent volume;

- Using the test chamber directly as the sample cell has very little free volume, which can effectively utilize the test chamber space and is more conducive to foaming materials with high porosity.

- The sample cell needs to be placed in the testing chamber, which has a large free volume for testing. Standard substances such as aluminum blocks and steel balls need to be used to fill the free volume. The utilization rate of the testing chamber space can only reach 50%, which is not suitable for testing foam materials with high porosity

Test Data